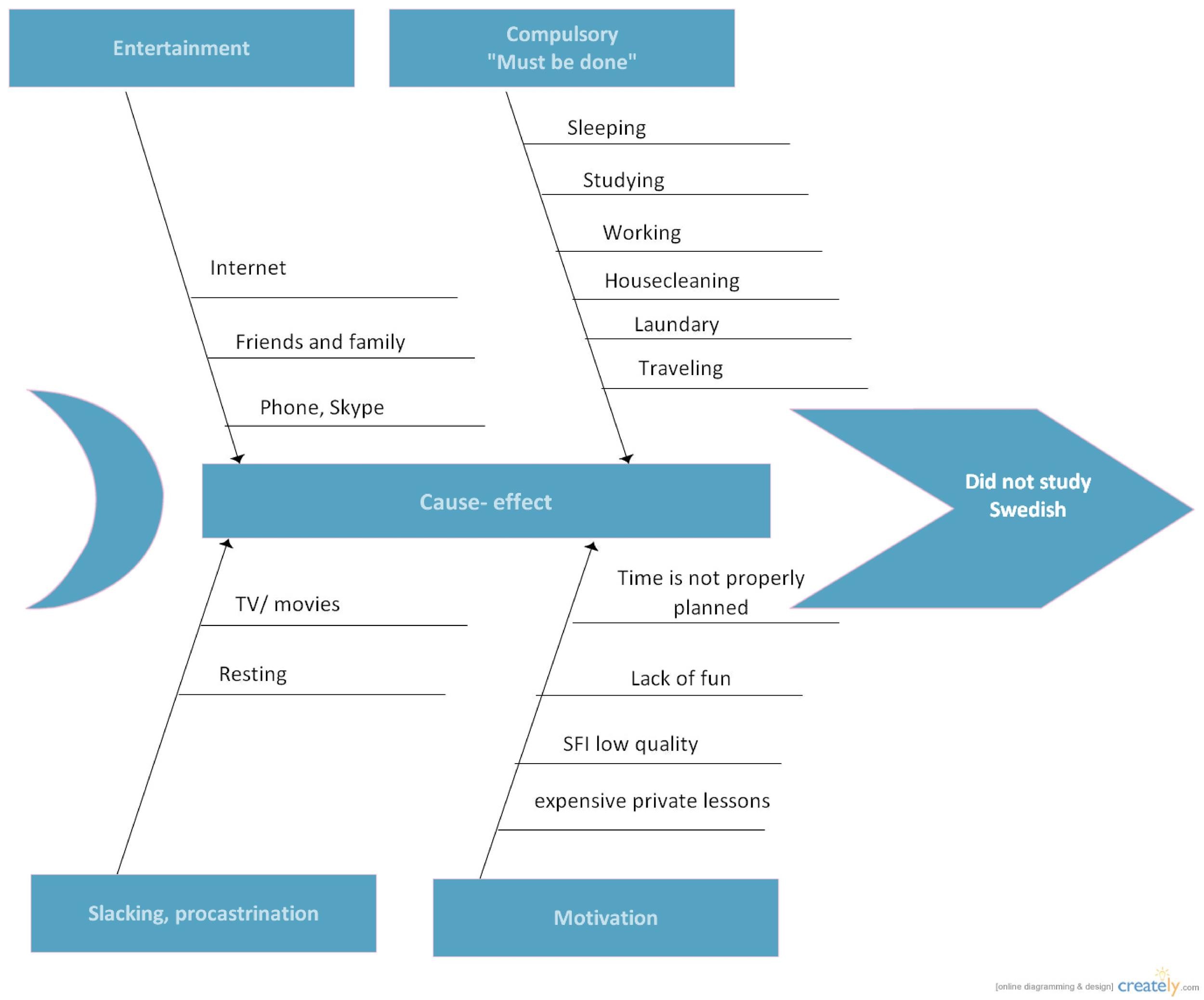

The purpose of this study is to investigate cornerstone root causes through the application of CEDs in 40 Mexican companies that began an effort to improve some of their organizational processes. Kaoru Ishikawa created the fishbone diagram structure, so you’ll also see them referred to as Ishikawa diagrams or cause and effect diagrams. Exploring this questioning can shed light on the first indications to ratify the arguments of Ishikawa and Deming, that the main problems of companies are found in their processes and perhaps, in a deep way, in some of these cornerstone root causes that have to do with the way organizations are managed. A fishbone diagram is a way to visually represent the potential causes of an event or problem. In this group of quality tools is the cause-and-effect diagram (CED), also known as “The Fishbone” and “Ishikawa diagram”. Kaoru Ishikawa proposes seven basic quality tools. Some of these efforts use quality control tools to remedy it. It can become a highly effective tool to identify the areas and problems that are limiting your well-being. It can also become an ideal strategy in the area of personal growth. As we pointed out above, the Ishikawa diagram doesn’t have to be limited to social and business spheres. The elimination of problems and waste (MUDA for the Japanese) plays a fundamental role in the reduction of operational costs and quality rejections of finished products both internally in the organization and in the supply chain. The Ishikawa diagram for personal growth.

Some manufacturing and service organizations have made efforts to work on continuous improvement in the form of Kaizen, lean thinking, Six Sigma, etc.

0 kommentar(er)

0 kommentar(er)